For over 30 years, Bob's Granite Place of New Hampshire has been a leading quartz, granite and stone countertop sales, fabrication and installation company. We've installed literally tens of thousands of countertops, sinks and cabinets for every imaginable indoor and outdoor project.

Because of our extensive experience, we thought it would be a good idea to put together (and update) our own "quartz versus granite" comparison document to help you select between these two, very different, durable and equally popular materials.

So What's a Granite Countertop?

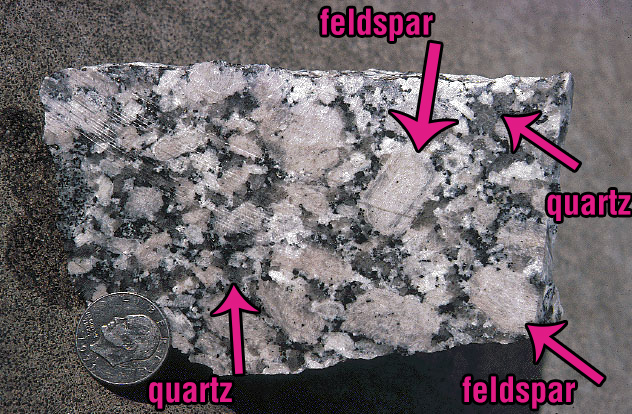

Granite is a natural material (an igneous rock) that starts off as a very hot molten "stew of minerals" that ultimately cools and crystallizes beneath the earth's surface. Erosion eventually makes it possible for specialists to find, then test, and hopefully mine for granite and other natural materials.

Fortunately, granite is extremely abundant throughout the world. Yet, only certain varieties are mined for countertop use. Generally, the most desirable varieties are finer grained white or black, and those that contain at least 20% of the mineral quartz. Feldspar is also important - and it's essentially as hard as quartz

Together, quartz and feldspar make up 70-85% of most granite countertops. The remaining minerals account for many unique colorations and veining. These other materials include micas, amphiboles, and various other trace minerals.

Granite is incredibly strong and durable because its minerals orient into interlocking crystals as they solidify. This makes granite incredibly scratch resistant, heat resistant and very low in porosity. Its complex "gemstone-like" structure (on polished counters) also refracts incoming light as your angle of view changes. This color property is referred to as "depth of color" or "color movement."

So What's a Quartz Countertop?

Unlike other stone counters, "quartz countertops" are actually part of a class of manufactured materials known as "engineered surfaces." This doesn't make them bad. It just means you are not buying something that's 100% natural (as most manufacturers claim).

Actually, the first "engineered surface" countertop" was introduced by Dupont Corp. in 1971. This material was/is called a "solid surface" countertop and many colors and textures are available. Although they're not quite as durable as current engineered quartz, they can be a viable choice if you're on a tight budget and you don't treat your counters rough.

Quartz counters come in a wide range of colors and have excellent durability and scratch resistance. Some formulations actually look close to simpler granites, while others come close to matching simpler marbles and quartzites.

Quartz manufacturers describe their formulation chemistries using an initial weight percentage mixture ratio of solid materials versus chemical resins and other additives. Stated ratios vary between 88-97% solids and 3-12% resins and other chemicals. Basically, the resins are the glue that bind everything together.

To visualize an engineered quartz "mix" better, we prefer to use a volume percent ratio. With this approach, engineered quartz formulations vary between 24-35% polymer resin/chemicals and 65-76% solids. We prefer this approach because even cured resin is a very lightweight and soft material compared to the solids. Thus, you can visualize that quartz counters contain a significant volume of soft lightweight resin, which tends to slightly decrease their overall scratch resistance.

The current hardness (e.g., scratch resistance) of quartz counters is generally less than most granites - but not by a significant amount. To learn more about "mineral hardness," check out this article on granite versus quartz, published by a geologist from the Natural Stone Institute.

Quartz Manufacturing

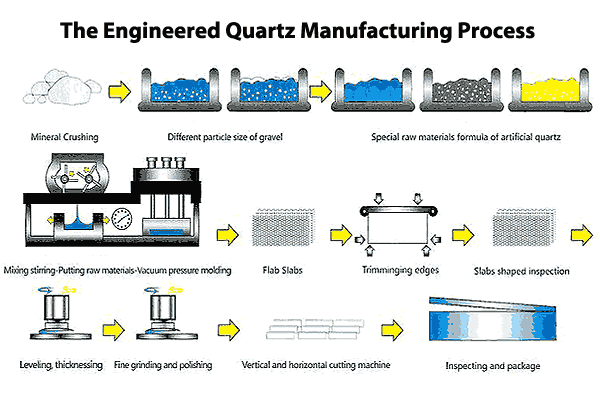

To make any quartz slab, a specified mixture of "solids and chemicals" are processed together using mixing, pressure, heat and vibration. The "solids" portion of the mix consists of very small (and sifted) grains of real quartz crystals. The solids can also include various types of sand grains, ground glass, metal flakes (to flicker light), and possibly silicone with mirrored glass (to simulate granite veining). The chemical portion includes polymer resins, resin stabilizers, UV breakdown inhibitors, and the pigments and/or dyes for coloration.

Quartz counters are manufactured in one of two ways. The most dominant method is known as the Bretonstone process (developed in Europe). It requires the use of very large inline heated vacuum vibration molding machines that mix and bond the solid particles with the resins and dyes while eliminating all air voids. Some versions of this process may also include a post molding heat curing step to further strengthen the slab. Trimming and surface finishing is the final step conducted on each slab - and is conducted very similarly to other stone counters.

The other manufacturing process (used by most Asian manufacturers) utilizes a heated press molding approach that pulls only a partial vacuum to reduce resin voiding. Thus, complete void removal is not possible. Moreover, this approach is best suited for low temperature resins.

The image below shows the entire Asian heat press, partial vacuum quartz countertop manufacturing process. To see this in greater detail, pinch the image wider on your mobile or 2-in-1 device.

NOTE: Today, some quartz formulations are now made with lower ratios of resin and higher temperature-rated resins (e.g., stable up to 440 degrees F versus 150 degree F). This is a higher temperature process that is ideal for Bretonstone manufacturers.

Although the higher temperature resin binder formulations reduce the chance of resin discoloration from heat exposure, if very hot objects (like pots and pans) contact surfaces near sink cutouts or edges, deep cracks can form and cannot be repaired. This occurs because the lower quantity of resin binders enables thermal shock cracking to occur. Fortunately, this can be completely avoided by NOT putting hot objects on top of quartz countertops.

Quartz and Granite Counter Prices.

While granite countertop prices have increased only slightly in 2023- 2024, quartz countertop prices have risen more dramatically. Unfortunately, when you do a Google search on quartz versus granite pricing, you may see the opposite stated. However, when you price materials out, this becomes clear very quickly.

To protect the U.S. quartz counter industry from product dumping by China and India in 2020-2022, the U.S. government added tariffs to both countries' products. This helped quartz counter prices during this time.

Fortunately, the upward trend in quartz pricing has slowed as of this writing, but has not decreased. Meanwhile, the pricing of granite and other natural stone counters has remained quite stable overall. This trend is expected to continue.

Here's a material pricing comparison;

Granite: For a 3-cm (~1.25-inch) granite countertop slab in New Hampshire, low to mid-range price is between $30.00 and $55.00 per square foot. For moderate to high-end granite slabs, pricing will range between $60.00 and $175.00 per square foot.

Quartz: Comparing quartz colors prices to comparable granite colors, quartz countertop slab prices start at $34.00 per square foot and go up from there. In general, quartz pricing is 30-50% higher than any equivalent granite. And for solid color quartz slabs (e.g., white, off-white, red, green, orange and blue) expect to pay between $80.00 and $225.00 per square foot - since there's no competition from any natural stone.

The industry standard thickness for all kitchen countertops is 3-cm (~1.25-inch). This is important to know because some countertop suppliers will quote "supposedly comparable" slab prices based on thinner 2-cm (~3/4-inch) material without letting you know.

The final installed price for any countertop will depend on many additional factors. For more information on what these are, please read our countertop buying and installation guide.

Granite and Quartz Colors and Finishes.

Granite Colors

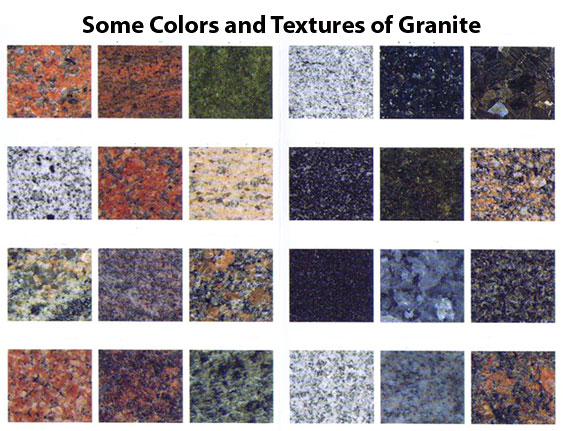

Granite counters come in a wide range of unique colors, names and finishes - which is a big reason why they remain so appealing. As previously mentioned, the 3D "color movement" of polished versions is totally unique to all other countertop materials.

Since all countertop color naming has become quite confusing, we recommend that you focus on the main granite color categories during your search. These are beige, black, blue, brown, burgundy, gray, green, red, yellow, and white.

And even though no two slabs of natural granite from the same mine are exactly the same, similarities in their composition enable them to be identified, quarried and classified precisely. See our popular granite colors and names page to see what we mean.

Finally, granite counters are available in polished (glossy), honed, or leather surface finishes.

Engineered Quartz Colors

As was previously mentioned, engineered quartz gets its coloration from the addition of materials such as pigments and/or dyes, metal flakes, mirrored glass and more. However, quartz coloration is not three-dimensional. Visit our quartz countertop page to see some of our product lines and the quartz countertop colors we offer.

Engineered quartz uniquely offers solid (monochromatic) colors can be stunning or gaudy. Currently, solid color choices include whites, off-whites, reds, oranges, greens and blues. If such colors are important to you, then engineered quartz will be your only choice. Just be prepared for a hefty price tag.

Finally, quartz countertop manufacturers offer their materials in polished, honed, sandblasted, and embossed surface finishes. However, polished versions do not have the same kind of luster as comparable natural stone.

A solid blue (monochromatic) piece of engineered quartz .

A polished, solid white (monochromatic) engineered quartz countertop.

Heat Resistance: Quartz and Granite.

Granite fully melts at approximately 2400 degrees F (an unlikely home temperature scenario). It also does not support combustion, nor does it crack or discolor when objects are placed onto its surface.

Although quartz counters do not technically melt, low cost versions can sag or warp when subjected to heat. Most tend to discolor due to resin burn, if a hot object (typically over 150 degrees F) is placed directly onto its surface (such as a hot pot, pan, or dish). Such damage is NOT repairable.

For mid-to-high priced quartz formulations with higher temperature resins and very high ratios of solids to resin (make sure to ask if there is a temperature rating), the burn point can be up to 440 degrees F. However, the reduced quantity of resin can result in deep cracking if hot objects are placed onto their surfaces- especially near sink cutouts or edges. This type of damage is also NOT repairable.

Our advice is to simply avoid placing any hot items directly onto either quartz or granite countertops. There's no reason to take a chance on damaging the surface of a quartz counter, or to burn yourself by leaving a hot spot on a granite surface!

Are Quartz and Granite Counters Fireproof?

Short answer: Engineered quartz counters are not 100% fireproof, while granite countertops are completely fireproof. But what does this really mean?

Well, at this point in the evolution of man-made quartz countertops, the lowest grades of this material can support combustion (due to the higher quantity of lower temperature resin binders used). However, most Bretonstone process materials no longer support continuous combustion.

For further context, no grade of engineered quartz will ever start a fire, since they do not burn as readily as wood or other materials found in any building. In addition, there are many other materials that will produce more noxious gases in a home or business. Thus, quartz products should not be considered as inherently unsafe in a home or a business.

Durability and Scratch Resistance.

Both quartz and granite countertops are extremely durable materials. However, durability and scratch resistance are two different things. Using Moh's scale (a geologic measurement method that indicates comparative material scratch resistance - with a higher number meaning a greater scratch resistance) granite has a rating between 6 and 7 (where 10 is diamond and 5 is metal cutlery).

Quartz counters have a hardness value that varies between 5 and 6. This is the case due to the significant amount of "very soft" polymer resin binder they contain.

However, keep in mind that since your steel utensils have a hardness value between 5 and 6, there's really very little real difference in scratch resistance between engineered quartz or granite. Moreover, you should never use your countertop as a cutting board anyway!

Are Granite and Quartz Chip Resistant?

As long as you use small overhangs, 3-cm thick slab material, and your fabricator mills at least 1/4-inch rounded or "radiused" edges (versus sharp 90° edges) then chipping of either engineered quartz or granite countertops is highly unlikely. However, should a chip occur, both countertop types can be repaired in most cases.

Are Granite and Quartz Chemical Resistant?

Highly alkaline or acidic cleaning chemicals (like dyes, bleaches, and many solvents) can permanently discolor engineered quartz. This is why quartz countertop stain protectants are now recommended. They are easy to apply and worth the protection they afford. Granites are not perfect, but are nearly chemically inert - especially those pre-treated with protective nano coatings.

With granite counters, even if a chemical (or some other material) ends up dulling or hazing the surface, you can always buff it down. Resealing is a very simple process that takes about five to ten minutes.

Are Quartz and Granite "Green Materials?"

Most quartz countertop manufacturers state that their product is a "green material" with a lower carbon footprint than granite. Let's review this marketing claim.

First off, both engineered quartz and granite are shipped from all over the world, and weigh essentially the same. Thus, they both consume a similar amount of carbon to arrive at their final installation locations.

Second, since granite is a 100% natural material, it seems quite odd that a manufactured material could ever claim to be a "green material?" Yet, such nonsensical statements are made by the marketing departments of engineered quartz companies - as well as from many "supposed" experts (whom are being paid by engineered quartz manufacturers to tout their products).

From our perspective, it's really more important to maintain your focus on the actual pros and cons of these two very durable countertop materials rather than getting lost in such meaningless statements.

Countertops and Seams.

For standard and solid colored quartz countertops, seams can be more visible than you might expect. This is because quartz seams are harder to match with the specific bonding/seam joining agents together with available dyes and pigments for color matching. Also, long term UV light exposure to seams and the primary surface resin can result in differential fading.

This highlights why quartz countertops should never be placed in direct sunlight inside, and should NEVER be chosen for outdoor use. Granite, or other natural stone counters, are the only choice for direct sunlight applications.

Are Granite and Quartz Countertops Porous?

The polymer resins in engineered quartz counters make them essentially non-porous. Non-porous surfaces are generally considered a positive attribute for kitchen and bathroom applications since the potential for bacterial growth can be minimized - assuming you regularly clean your countertops!

Although some varieties of granite can be slightly porous, most granite fabricators now add a special nano-coating sealant that lasts up to 15 years. However, once again, you must regularly clean BOTH types of countertops to maintain such sanitary conditions. A non porous surface alone will not ensure "zero" bacterial growth!

Finally, the company you choose to purchase and install a granite countertop should guaranty its sealant for whatever it is rated for.

Are Granite and Quartz Countertops Good for Outdoor Use?

Granite is. Quartz is not. The ultraviolet breakdown inhibitors added to engineered quartz resin during the manufacturing process, still continually degrade the resin and color additives with exposure to the ultraviolet light from the sun. This results in color fading, potential warping/cracking, and strength reduction.

As a result, engineered quartz counters are not recommended for outdoor use or for indoor use in direct sunlight. In contrast, granite countertops excel for all indoor and outdoor applications.

So How Do I Choose Between Granite and Quartz?

Our advice is that if you prefer two-dimensional marble-like colorations or solid, non-textured colorations then you may want to pay extra for engineered quartz counters - but only for indoor use.

If you need an indoor/outdoor material, and/or one with a unique 3D coloration and texture, then a granite countertop will be the best choice at the best price.

If you want to "see" what quartz and granite countertop colors will be best for you, then please try our online kitchen and countertop design tool. With it, you can vary cabinet color, flooring and backsplash designs in order to help you pick out an ideal granite or quartz countertop!

Granite and Quartz Countertops and Home Value.

On average, granite and quartz countertop installations reportedly add their installed cost to the value of your home. Since kitchens and bathrooms are the most important rooms for increasing overall home value, choosing a durable countertop in these areas is usually a wise decision. If taken care of properly, both granite and quartz countertops will likely last well over 25 years.

Get Your "We

Call You" Countertop Estimate!

We'll call you back within 24-hours!

(Personal info not used for anything else!)